Malinga ndi kafukufuku ndi kusanthula, dzimbiri ndi chimodzi mwazinthu zofunika zomwe zimawononga mavavu agulugufe.Chifukwa chakuti mkati mwake mumalumikizana ndi sing'angayo, imakhala ndi dzimbiri.Pambuyo pa dzimbiri, m'mimba mwake valavu amakhala ang'onoang'ono ndi otaya kukana kumawonjezeka, zomwe zimakhudza kufala kwa sing'anga.Pamwamba pa thupi la valve nthawi zambiri amaikidwa pansi kapena pansi.Kumwamba kumakhudzana ndi mpweya ndipo mpweya umakhala wonyowa, choncho umakonda dzimbiri.Mpando wa valve umaphimbidwa kwathunthu pomwe mkati mwamkati umalumikizana ndi sing'anga.Chifukwa chake, njira yotetezera pamwamba pa thupi la valve ndi mbale ya valve ndiyo njira yotsika mtengo kwambiri yotetezera ku dzimbiri kunja kwa chilengedwe.

1. Udindo wa zokutira pamwamba pa gulugufe

01. Chizindikiritso cha zinthu zakuthupi za vavu

Mtundu wosanjikiza pamwamba umagwiritsidwa ntchito pamalo osagwirizana ndi ma valve ndi bonnet.Kupyolera mu chizindikiro cha mtundu uwu, tikhoza kudziwa mwamsanga zinthu za thupi la valve ndikumvetsetsa bwino makhalidwe ake.

| Vavu Thupi Zofunika | Mtundu wa Paint | Vavu Thupi Zofunika | Mtundu wa Paint |

| Kuponya Chitsulo | Wakuda | Chitsulo cha Ductile | Buluu |

| Chitsulo Chopangidwa | Wakuda | WCB | Imvi |

02. Kuteteza mphamvu

Pambuyo pa valavu ya thupi itakutidwa ndi utoto, thupi la valve limakhala lotalikirana ndi chilengedwe.Izi zoteteza zimatha kutchedwa kuti chitetezo.Komabe, ziyenera kunenedwa kuti utoto wochepa thupi sungathe kupereka chitetezo chokwanira.Chifukwa ma polima ali ndi mpweya wokwanira, pamene zokutira zimakhala zoonda kwambiri, ma pores apangidwe amalola kuti madzi ndi mamolekyu a oxygen azidutsa momasuka.Mavavu osindikizira ofewa amakhala ndi zofunikira zolimba pa makulidwe a zokutira za epoxy resin pamtunda.Pofuna kukonza kusasunthika kwa zokutira, zokutira zotsutsana ndi dzimbiri ziyenera kugwiritsa ntchito zinthu zopanga filimu zokhala ndi mpweya wochepa komanso zodzaza zolimba zokhala ndi chitetezo chachikulu.Panthawi imodzimodziyo, chiwerengero cha zigawo zophimba ziyenera kuwonjezereka kuti kupaka kumafika pamtundu wina ndipo kumakhala kowawa komanso kopanda porous.

03.Kuletsa dzimbiri

Zigawo zamkati za utoto zimachita ndi zitsulo kuti zidutse pamwamba pazitsulo kapena kupanga zinthu zoteteza kuti ziteteze chitetezo cha zokutira.Kwa ma valve omwe ali ndi zofunikira zapadera, muyenera kumvetsera zojambulazo kuti mupewe zotsatira zoyipa.Kuphatikiza apo, mavavu achitsulo omwe amagwiritsidwa ntchito m'mapaipi amafuta amathanso kukhala ngati organic corrosion inhibitors chifukwa cha zinthu zowonongeka zomwe zimapangidwa ndi mafuta ena komanso kuyanika kwa sopo zachitsulo.

04. Chitetezo cha electrochemical

Pamene ❖ kuyanika kolowera kwa dielectric kukakumana ndi chitsulo pamwamba, dzimbiri la electrochemical pansi pa filimuyo lidzapanga.Zitsulo zokhala ndi ntchito zambiri kuposa chitsulo zimagwiritsidwa ntchito ngati zodzaza zokutira, monga zinki.Idzagwira ntchito yoteteza ngati nsembe ya anode, ndipo zinthu zowonongeka za nthaka ndizochokera mchere wa zinki kolorayidi ndi nthaka carbonate, zomwe zidzadzaza mipata mufilimuyi ndikupanga filimuyo kukhala yolimba, kuchepetsa kwambiri dzimbiri ndi kupititsa patsogolo moyo wautumiki. valavu.

2. Zopaka zomwe zimagwiritsidwa ntchito pazitsulo zazitsulo

Njira zochizira pamwamba pa mavavu makamaka zimaphatikizapo zokutira utoto, galvanizing ndi zokutira ufa.Nthawi yoteteza utoto ndi yaifupi ndipo singagwiritsidwe ntchito pansi pa ntchito kwa nthawi yaitali.The galvanizing ndondomeko makamaka ntchito mapaipi.Onse otentha-dip galvanizing ndi electro-galvanizing ntchito.Njirayi ndi yovuta.Kukonzekera kumagwiritsa ntchito pickling ndi phosphating njira.Padzakhala zotsalira za asidi ndi zamchere pamwamba pa workpiece, kusiya dzimbiri Kuopsa kobisika kumapangitsa kuti wosanjikiza wamalata ukhale wosavuta kugwa.Kukana kwa dzimbiri kwa zitsulo zotayidwa ndi zaka 3 mpaka 5.Kupaka kwa ufa komwe kumagwiritsidwa ntchito m'mavavu athu a Zhongfa kumakhala ndi mawonekedwe a zokutira wandiweyani, kukana kwa dzimbiri, kukana kukokoloka, ndi zina zambiri, zomwe zimatha kukwaniritsa zofunikira zama valve pansi pamikhalidwe yogwiritsira ntchito madzi.

01. Vavu thupi epoxy utomoni zokutira

Lili ndi izi:

· Kukana kwa dzimbiri: Mipiringidzo yachitsulo ya epoxy resin-resin imakhala ndi kukana kwa dzimbiri, ndipo mphamvu yomangirira ndi konkire imachepetsedwa kwambiri.Iwo ndi oyenera mikhalidwe mafakitale m'madera chinyezi kapena zowononga TV.

·Kumamatira mwamphamvu: Kukhalapo kwa magulu a polar hydroxyl ndi ma ether bond omwe ali mu epoxy resin molecular chain kumapangitsa kuti ikhale yomatira kwambiri kuzinthu zosiyanasiyana.Kuchepa kwa utomoni wa epoxy akachiritsidwa kumakhala kochepa, kupsinjika kwamkati komwe kumapangidwa kumakhala kochepa, ndipo chophimba pamwamba pachitetezo sichapafupi kugwa ndikulephera.

· Mphamvu zamagetsi: Makina ochiritsidwa a epoxy resin ndi chida chabwino kwambiri chotchingira chokhala ndi ma dielectric apamwamba, kukana kutayikira pamwamba, komanso kukana kwa arc.

·Mold Resistant: Makina ochiritsa a epoxy resin amalimbana ndi nkhungu zambiri ndipo amatha kugwiritsidwa ntchito m'malo otentha kwambiri.

02. Vavu mbale nayiloni mbale zakuthupi

Mapepala a nayiloni ndi osagwirizana kwambiri ndi dzimbiri ndipo akhala akugwiritsidwa ntchito bwino pazinthu zambiri monga madzi, matope, chakudya ndi kuchotsa mchere m'madzi a m'nyanja.

·Kugwira ntchito panja: Chophimba cha nayiloni chikhoza kuyesa mayeso opopera mchere.Sanasendeke atamizidwa m’madzi a m’nyanja kwa zaka zoposa 25, choncho sipakhala dzimbiri pazigawo zachitsulo.

·Kukana kuvala: Kukana kuvala kwabwino kwambiri.

· Kusasunthika kwamphamvu: Palibe zizindikiro za kusuluka ndi mphamvu yamphamvu.

3. Kupopera mbewu mankhwalawa

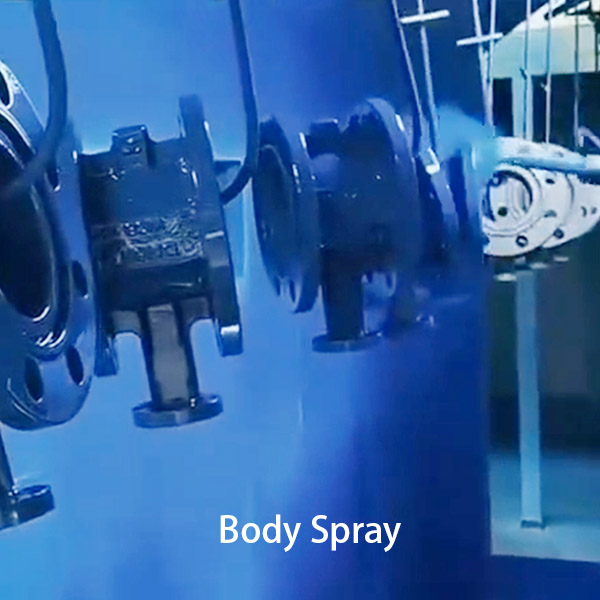

Kupopera mbewu mankhwalawa ndi pretreatment workpiece → kuchotsa fumbi → preheating → kupopera mbewu mankhwalawa (primer - trimming - topcoat) → solidification → kuzirala.

Kupopera mbewu mankhwalawa makamaka amagwiritsa ntchito electrostatic kupopera mbewu mankhwalawa.Malinga ndi kukula kwa workpiece, electrostatic kupopera mbewu mankhwalawa akhoza kugawidwa mu ufa electrostatic kupopera mbewu mzere kupanga ndi ufa electrostatic kupopera mbewu mankhwalawa unit.Njira ziwirizi ndizofanana, ndipo kusiyana kwakukulu ndi njira yosinthira ya workpiece.Mzere wopangira utsi umagwiritsa ntchito tcheni chopatsirana potengera zodziwikiratu, pomwe gawo lopopera limakwezedwa pamanja.Kuchuluka kwa zokutira kumayendetsedwa pa 250-300.Ngati makulidwe ake ndi ochepera 150 μm, ntchito yoteteza imachepetsedwa.Ngati makulidwe ake ndi aakulu kuposa 500 μm, zomatira zomatira zidzachepa, kukana kwamphamvu kudzachepa, ndipo kumwa ufa kumawonjezeka.