Malinga ndi kafukufuku ndi kusanthula, dzimbiri ndi chimodzi mwa zinthu zofunika kwambiri zomwe zimayambitsa kuwonongeka kwa ma valve a gulugufe. Chifukwa chakuti mkati mwake muli ndi cholumikizira chamkati, chimawonongeka kwambiri. Pambuyo pa dzimbiri, m'mimba mwake wa valavu mumakhala wochepa ndipo kukana kwa madzi kumawonjezeka, zomwe zimakhudza kufalikira kwa cholumikizira chamkati.pamwamba pa thupi la valavuKawirikawiri imayikidwa pansi kapena pansi pa nthaka. Pamwamba pake pamakhala mpweya ndipo mpweya ndi wonyowa, kotero umakhala ndi dzimbiri. Mpando wa valavu umaphimbidwa kwathunthu pomwe mkati mwake muli ndi cholumikizira. Chifukwa chake, kuphimba pamwamba pa thupi la valavu ndi mbale ya valavu ndiyo njira yotsika mtengo kwambiri yotetezera ku dzimbiri m'malo akunja.

1. Udindo wa chophimba pamwamba pa valavu ya gulugufe

01. Kuzindikiritsa zinthu za thupi la valavu

Mtundu wa pamwamba pa valavu umayikidwa pamalo osapangidwa a thupi la valavu ndi bonnet. Kudzera mu chizindikiro cha utoto ichi, titha kudziwa mwachangu zinthu za thupi la valavu ndikumvetsetsa bwino mawonekedwe ake.

| Zida za Thupi la Vavu | Mtundu wa Utoto | Zida za Thupi la Vavu | Mtundu wa Utoto |

| Chitsulo Chopangidwa | Chakuda | Chitsulo Chopangidwa ndi Ductile | Buluu |

| Chitsulo Chopangidwa | Chakuda | WCB | Imvi |

02. Mphamvu yoteteza

Pambuyo poti pamwamba pa thupi la valavu papakidwa utoto, pamwamba pa thupi la valavu pamakhala kutali ndi chilengedwe. Mphamvu yoteteza iyi imatha kutchedwa mphamvu yoteteza. Komabe, ziyenera kudziwika kuti utoto wochepa sungapereke mphamvu yoteteza kwathunthu. Chifukwa ma polima ali ndi mphamvu yopumira, pamene chophimbacho chili chopyapyala kwambiri, ma pores omangira amalola madzi ndi mamolekyu a okosijeni kudutsa momasuka. Ma valve otseka ofewa ali ndi zofunikira kwambiri pa makulidwe a epoxy resin pamwamba. Pofuna kukonza kulimba kwa chophimbacho, zokutira zotsutsana ndi dzimbiri ziyenera kugwiritsa ntchito zinthu zopangira filimu zomwe zimakhala ndi mpweya wochepa komanso zodzaza zolimba zomwe zimakhala ndi mphamvu zoteteza kwambiri. Nthawi yomweyo, kuchuluka kwa zigawo zokutira kuyenera kuwonjezeredwa kuti chophimbacho chifike makulidwe enaake ndipo chikhale chokhuthala komanso chopanda mabowo.

03. Kuletsa dzimbiri

Zinthu zamkati mwa utoto zimagwirizana ndi chitsulo kuti zichepetse pamwamba pa chitsulo kapena kupanga zinthu zoteteza kuti ziwongolere mphamvu yoteteza ya utoto. Pa mavavu okhala ndi zofunikira zapadera, muyenera kusamala ndi kapangidwe ka utoto kuti mupewe zotsatirapo zoyipa kwambiri. Kuphatikiza apo, mavavu achitsulo opangidwa ndi chitsulo omwe amagwiritsidwa ntchito m'mapaipi amafuta amathanso kugwira ntchito ngati zoletsa dzimbiri chifukwa cha zinthu zomwe zimapangidwa ndi mafuta ena komanso sopo wachitsulo wouma.

04. Chitetezo cha zamagetsi

Pamene chophimba cholowera cha dielectric chikakhudzana ndi pamwamba pa chitsulo, dzimbiri la electrochemical pansi pa filimuyi lidzapangidwa. Zitsulo zomwe zimakhala ndi ntchito yochulukirapo kuposa chitsulo zimagwiritsidwa ntchito ngati zodzaza muzophimba, monga zinc. Zidzakhala ndi gawo loteteza ngati anode yopereka nsembe, ndipo zinthu zopangidwa ndi dzimbiri za zinc ndi zinc chloride ndi zinc carbonate zomwe zimapangidwa ndi mchere, zomwe zidzadzaza mipata mufilimuyi ndikupanga filimuyo kukhala yolimba, zomwe zimachepetsa kwambiri dzimbiri ndikuwonjezera moyo wa valavu.

2. Zophimba zomwe zimagwiritsidwa ntchito kwambiri pa ma valve achitsulo

Njira zochizira pamwamba pa ma valve makamaka zimaphatikizapo utoto, galvanizing ndi ufa. Nthawi yoteteza utoto ndi yochepa ndipo singagwiritsidwe ntchito nthawi yayitali. Njira yochizira galvanizing imagwiritsidwa ntchito kwambiri m'mapaipi. Zonse ziwiri zochizira galvanizing zotentha komanso zamagetsi zimagwiritsidwa ntchito. Njirayi ndi yovuta. Kuchizira kusanachitike kumagwiritsa ntchito njira zochizira ndi phosphate. Padzakhala zotsalira za asidi ndi alkali pamwamba pa workpiece, zomwe zimasiya dzimbiri. Ngozi yobisika imapangitsa kuti galvanizing isagwe mosavuta. Kukana dzimbiri kwa chitsulo chochizira ndi zaka 3 mpaka 5. Kuphimba ufa komwe kumagwiritsidwa ntchito mu ma valve athu a Zhongfa kuli ndi mawonekedwe a kupaka kokhuthala, kukana dzimbiri, kukana kukokoloka kwa nthaka, ndi zina zotero, zomwe zingakwaniritse zofunikira za ma valve pansi pa mikhalidwe yogwiritsira ntchito madzi.

01. Chophimba cha epoxy resin cha thupi la valavu

Ali ndi makhalidwe awa:

·Kukana dzimbiri: Mipiringidzo yachitsulo yokhala ndi epoxy resin imakhala ndi kukana dzimbiri bwino, ndipo mphamvu yolumikizana ndi simenti imachepa kwambiri. Ndi yoyenera mafakitale okhala ndi chinyezi kapena malo owononga.

·Kugwirizana mwamphamvu: Kukhalapo kwa magulu a polar hydroxyl ndi ma ether bond omwe amapezeka mu unyolo wa epoxy resin kumapangitsa kuti ikhale yogwirizana kwambiri ndi zinthu zosiyanasiyana. Kuchepa kwa epoxy resin ikachiritsidwa kumakhala kochepa, kupsinjika kwamkati komwe kumachitika kumakhala kochepa, ndipo chophimba choteteza pamwamba sichimagwa mosavuta ndikulephera.

·Makhalidwe amagetsi: Dongosolo la epoxy resin lokonzedwa bwino ndi chinthu chabwino kwambiri chotetezera kutentha chomwe chili ndi mphamvu zambiri za dielectric, kukana kutuluka kwa madzi pamwamba, komanso kukana arc.

·Yosagwira Nkhungu: Dongosolo la epoxy resin lokonzedwa bwino limalimbana ndi nkhungu zambiri ndipo lingagwiritsidwe ntchito m'malo otentha kwambiri.

02. Zida za mbale ya valavu ya nayiloni

Mapepala a nayiloni ndi olimba kwambiri ndipo agwiritsidwa ntchito bwino m'njira zambiri monga madzi, matope, chakudya ndi kuchotsa mchere m'madzi a m'nyanja.

·Kugwira ntchito kwakunja: Chophimba cha nayiloni chimatha kupambana mayeso a mchere. Sichinachotsedwe pambuyo pomizidwa m'madzi a m'nyanja kwa zaka zoposa 25, kotero palibe dzimbiri ku zitsulo.

·Kukana kuvala: Kukana kuvala bwino kwambiri.

·Kukana kukhudzidwa: Palibe zizindikiro zoti zimayamba kung'ambika pakagwa mphamvu.

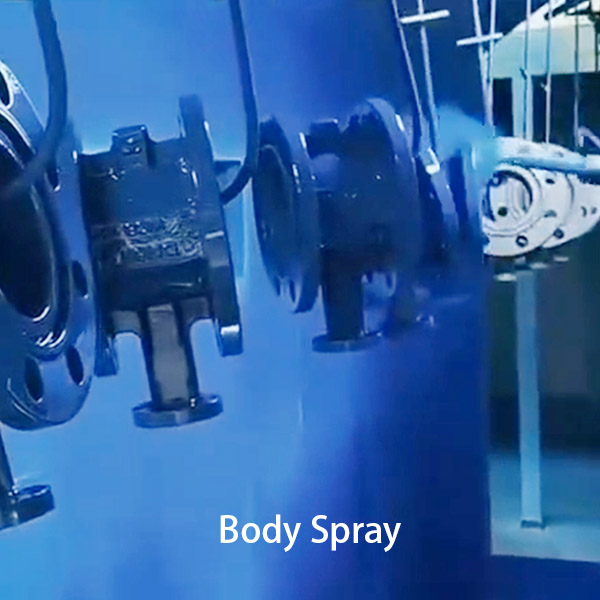

3. Njira yopopera

Njira yopopera ndi yokonzekera ntchito → kuchotsa fumbi → kutentha → kupopera (primer - kudula - topcoat) → kulimbitsa → kuziziritsa.

Kupopera Kupopera Kupopera kumagwiritsa ntchito kupopera kwa electrostatic. Malinga ndi kukula kwa workpiece, kupopera kwa electrostatic kungagawidwe m'magulu awiri: mzere wopanga kupopera kwa electrostatic ndi unit wa powder electrostatic. Njira ziwirizi ndi zofanana, ndipo kusiyana kwakukulu ndi njira yosinthira ya workpiece. Mzere wopanga kupopera umagwiritsa ntchito unyolo wotumizira kuti uperekedwe mwachangu, pomwe unit wopopera umakwezedwa pamanja. Kukhuthala kwa kuvala kumayendetsedwa pa 250-300. Ngati makulidwe ndi ochepera 150 μm, magwiridwe antchito oteteza adzachepetsedwa. Ngati makulidwe ndi opitilira 500 μm, kumatirira kwa kuvala kudzachepa, kukana kukhudzidwa kudzachepa, ndipo kugwiritsa ntchito ufa kudzawonjezeka.