A valavu ya butterfly yokhala ndi mzere wokwaniraimakhala ndi mzere wokwanira mkati mwa thupi la valve. Kapangidwe kameneka kamapangidwa kuti azigwira ntchito zolimbana ndi dzimbiri.

"Kutsekedwa kwathunthu" kumatanthauza kuti si diski yokhayo yomwe imatsekedwa kwathunthu, komanso mpando umatsekedwa kwathunthu, kuonetsetsa kudzipatula kwathunthu pakati pa zofalitsa ndi zitsulo.

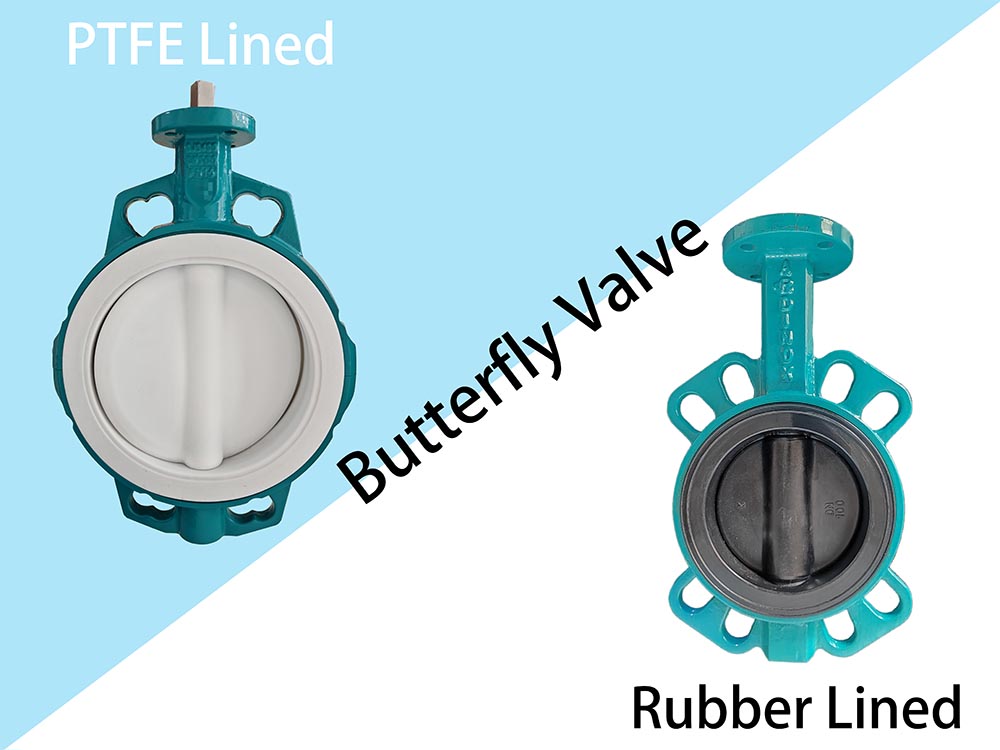

1. Zida ziwiri zomwe zimagwiritsidwa ntchito pazitsulo

a. PTFE (polytetrafluoroethylene, perfluoroplastic) lining butterfly valve

b. Valve ya gulugufe wokhala ndi mphira

| Mtundu Wazinthu: | Polytetrafluoroethylene (PTFE). | Kuyika kwa mphira (monga EPDM, Viton, NBR) |

| Lining Process | Molten PTFE/PFA imatsanuliridwa mu dovetail groove pathupi/dimba, kukwaniritsa chomangira chopanda msoko. | Kenako imatenthedwa mwachindunji (kutenthedwa) pachitsulo, ndikupanga chisindikizo cholimba. |

| Zofunika Kwambiri | - Kukana kwabwino kwa dzimbiri (kusagwirizana ndi pafupifupi ma acid onse, zoyambira, ndi zosungunulira organic) - Kukana kutentha kwakukulu (kutentha kosalekeza mpaka 180°C) - Kutsika kocheperako kocheperako komanso zinthu zopanda ndodo, zoyenera pazambiri zodziyeretsa kwambiri

| - Kuthamanga kwabwino kwambiri komanso kusindikiza bwino (kosavuta kukwaniritsa zero kutayikira) - Mtengo wotsika komanso kukana kuvala bwino kwa media zosawononga - Kukana kutentha kochepa (nthawi zambiri -20°C mpaka 180°C, kutengera mtundu wa rabala)

|

| Applicable Media | Ma asidi amphamvu (monga sulfuric acid ndi hydrochloric acid), maziko amphamvu, zosungunulira za organic, madzi oyeretsedwa kwambiri. | madzi, madzi otayira, ma asidi ofooka ndi maziko, slurries, ndi media-grade media |

| Ntchito Zofananira | Chemical Viwanda (acid ndi alkali transfer), Pharmaceutical Industry (high-purity material transfer) | Kuchiza kwa Madzi (kuyeretsa madzi onyansa, madzi apampopi), HVAC Systems, Makampani a Chakudya ndi Chakumwa, Mining (kutengerapo slurry) |

2. Tsatanetsatane Njira Masitepe kwa PTFE-mizere Vavu zimbale

2.1 Kukonzekera kwa Metal Disc

a.. Ponyani kapena makina chitsulo chimbale pachimake, kuonetsetsa kuti pamwamba ndi woyera ndi wopanda mafuta ndi kuipitsidwa.

b.. Dulani ma grooves (mawonekedwe a nkhunda) pachimake kuti mupereke mfundo za nangula za jakisoni wa PTFE ndikuletsa kuti zisagwe.

2.2 PTFE Powder Kuumba ndi Preforming

a. Ikani chiwerengero chowerengedwa bwino cha PTFE ufa (kapena premix) mu nkhungu, ikani pakatikati pazitsulo zamagulugufe agulugufe, ndikuwonjezera ufa wa PTFE.

b. Pang'onopang'ono ikani vacuum (utsi) ndi kukakamiza (kuponderezana kapena kukakamiza kwa isostatic) kuti mupange mluza wobiriwira. Kujambula kwa Isostatic: Kumiza nkhungu m'madzi ndikugwiritsa ntchito mphamvu zofanana kumbali zonse (kuthamanga kwa madzi) kuti muwonetsetse kuti mawonekedwe a yunifolomu ndi wandiweyani (porosity yotsika ngati <1%).

2.3 Kuwongolera ndi Kuwongolera

a. Ikani mluza wobiriwira mu uvuni ndikuwotcha pa 380 ° C kwa maola 5-24 (pang'onopang'ono onjezerani kutentha kuti mupewe ming'alu).

b. Pang'onopang'ono ozizira kutentha kutentha kulola PTFE crystallize ndi fuse ndi zitsulo pachimake, kupanga chosakanizira ❖ kuyanika (mawondomu ankalamulidwa kukhala 3-10mm, kusinthidwa malinga vacuum mikhalidwe).

2.4 Kupanga ndi Kumaliza:

Gwiritsani ntchito lathe kapena makina a CNC kusindikiza ma diameter amkati ndi akunja kuonetsetsa kuti chimbale ndi mpando zikugwirizana bwino (zololera ndizolimba, mwachitsanzo, ± 0.01mm).

2.5 Kuyang'ana Ubwino ndi Kuyesa:

a. Muyezo wa Makulidwe: Onetsetsani kuti mulingo wocheperako ukhale 3mm, kapena monga mwamakonda.

b. Kuyesa kwa Spark: 35,000 volts pakuyesa kulimba (palibe kusweka kukuwonetsa kuvomereza).

c. Kuyesa kwa Vacuum / Mphamvu: Imatengera momwe magwiridwe antchito amagwirira ntchito kuti awone kutayikira ndi kutulutsa (malinga ndi EN 12266-1 kapena API 598).

d. Mayeso a Conductivity (posasankha): Kukana kwapamwamba <10⁶Ω pazogwiritsa ntchito zomwe sizingaphulike.

3. Tsatanetsatane wa Njira Zopangira Ma disc okhala ndi EPDM

3.1 Kukonzekera kwa Metal Disc

a. Ponyani kapena makina pachimake chachitsulo kuti pakhale malo oyera, opanda dzimbiri.

b. Mchenga kapena mankhwala etch pamwamba (roughness Ra 3-6μm) kulimbikitsa EPDM adhesion.

3.2 EPDM Compound Application ndi Preforming

EPDM yosachiritsika (tsamba kapena madzi) imayikidwa mu nkhungu, kukulunga pakatikati pazitsulo. Pogwiritsa ntchito kuponderezana kapena kutsanulira, perekani mofanana pawiri pa diski ya valve kuti mupange thupi lobiriwira. Sungani makulidwe a 2-5 mm, kuwonetsetsa kufalikira kuzungulira m'mphepete mwa diski.

3.3 Kuwongolera

Thupi lobiriwira limayikidwa mu autoclave ndikutenthedwa ndi nthunzi kapena mpweya wotentha (150-180 ° C, kuthamanga> 700 psi, kwa maola 1-4).

Njira yochiritsira imagwirizanitsa ndikuchiritsa EPDM, kumangiriza ndi mankhwala ndi makina ku chitsulo chachitsulo kuti apange chinsalu chopanda msoko, chimodzi. Wonjezerani kutentha pang'onopang'ono kuti mupewe kuphulika kwa mpweya kapena ming'alu.

3.4 Kumaliza Machining

Mukaziziritsa, chepetsani m'mphepete mwamkati ndi kunja pogwiritsa ntchito lathe ya CNC kuti muwonetsetse kuti chimbale ndi mpando zikugwirizana bwino (kulekerera ± 0.05 mm). Chotsani mphira wowonjezera ndikuyang'ana mawonekedwe a m'mphepete (Kupaka kwa Ni-Cu ndikosankha kuti musamavalidwe bwino).

3.5 Kuyang'anira Ubwino ndi Kuyesa

a. Makulidwe ndi Mayeso Kumamatira: Akupanga makulidwe muyeso (osachepera 2mm); Kuyesa kwamphamvu (mphamvu ya peel> 10 N/cm).

b. Kutsimikizira Magwiridwe: Mayeso a Bubble Tight Seal (API 598 muyezo); Mayeso a Pressure/Vacuum (PN10-16, kukana kukakamiza koyipa).

c. Mayeso a Chemical / Ukalamba: Kumizidwa mu media acid ndi zamchere, kuyang'ana kukula <5%; Kukalamba kotentha kwambiri (120°C, 72h).

4. Kalozera Wosankha

PTFE linings ndi oyenera kuwononga kwambiri media (monga zidulo, alkalis, ndi zosungunulira), pamene EPDM linings ndi oyenera madzi, mild TV (monga madzi ndi dilute zidulo). Ikani patsogolo kaphatikizidwe ka mankhwala, kutentha, kuthamanga, ndi mtengo kuti mukwaniritse ntchitoyo. Zhongfa Valve imapanga mavavu agulugufe okhala ndi mizere yodzaza ndi zopyapyala, flange, ndi ma lug. Chonde titumizireni mafunso aliwonse.

Nthawi yotumiza: Oct-28-2025