Mavavu agulugufe olimbandi omwe amagwiritsidwa ntchito kwambiri ma valve agulugufe pamapaipi amakampani. Amagwiritsa ntchito zinthu zotanuka monga mphira ngati malo osindikizira, kudalira "kulimba kwa zinthu" ndi "kuponderezedwa kwapangidwe" kuti akwaniritse ntchito yosindikiza.

Nkhaniyi sikuti imangofotokoza za kamangidwe kake, kagwiritsidwe ntchito ka zinthu, kagwiritsidwe ntchito ka zinthu, komanso imasanthula kuchokera ku chidziwitso chambiri kupita kumalingaliro ozama.

1. Kumvetsetsa Kwambiri kwa Mavavu Agulugufe Okhazikika (Kufotokozera Mwachidule)

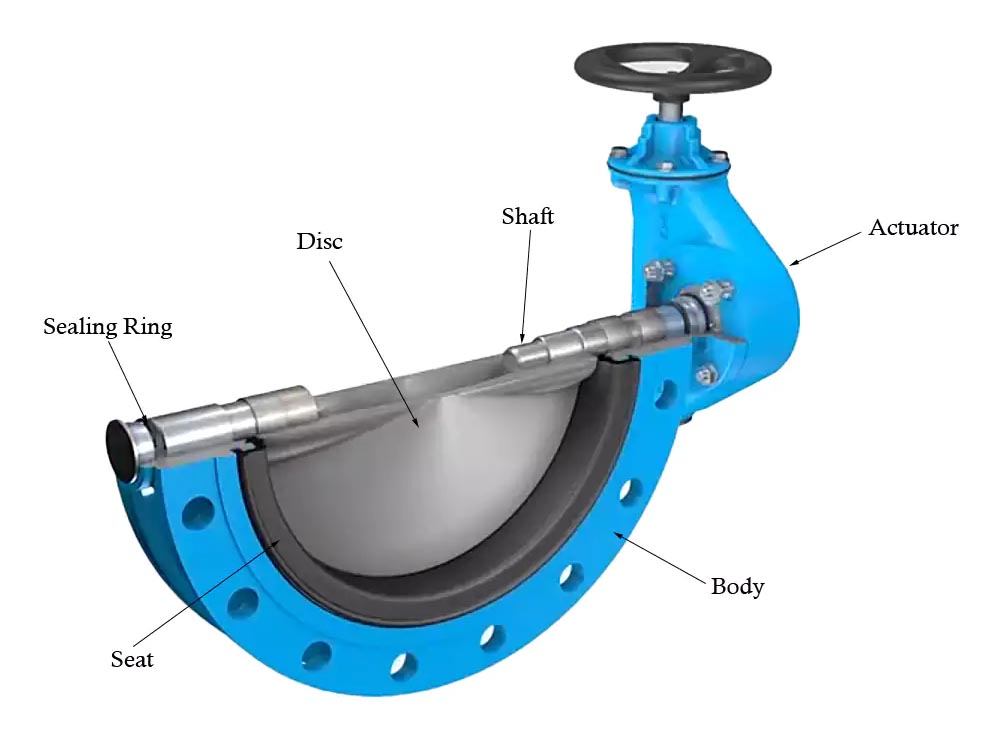

1.1 Mapangidwe Oyambira

Thupi la Vavu:Kawirikawiri mtundu wawafer, mtundu wa lug, kapena mtundu wa flanged.

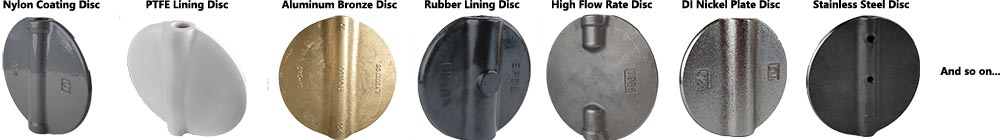

Valve Diski:Chophimba chachitsulo chozungulira chomwe chimakanikiza mpando wa rabara chikatsekedwa kuti chisindikize.

Mpando wa Valve:Zopangidwa ndi zinthu zotanuka monga NBR/EPDM/PTFE/Rubber Lined, zikugwira ntchito molumikizana ndi disc valve.

Tsinde la Vavu:Nthawi zambiri amagwiritsa ntchito shaft imodzi kapena iwiri shaft.

Woyambitsa:Handle, giya nyongolotsi, magetsi, pneumatic, etc.

1.2 Zomwe Zimafanana

Mulingo wosindikiza nthawi zambiri umapangitsa kuti ziro zitayike.

Mtengo wotsika komanso wosiyanasiyana wa ntchito.

Amagwiritsidwa ntchito kwambiri pamakina otsika mpaka apakatikati monga madzi, air conditioning, HVAC, ndi mafakitale opepuka.

2. Maganizo Olakwika Okhudza Ma Vavu Agulugufe Okhazikika

2.1 Chofunikira pakusindikiza ndikulimba kwa mphira

Anthu ambiri amakhulupirira kuti: "Mipando yokhazikika imadalira mphamvu ya rabara kuti isindikize."

Zofunika zenizeni za kusindikiza ndi:

Thupi la valavu + tsinde lapakati la valavu + makulidwe a valve disc + njira yoyika mpando wa valve

Pamodzi pangani "controlled compression zone".

Mwachidule:

Rabara sangakhale womasuka kwambiri kapena wothina kwambiri; imadalira "zosindikiza zosindikizira" zomwe zimayendetsedwa ndi makina olondola.

N’chifukwa chiyani zimenezi zili zofunika?

Kupanikizana kosakwanira: Vavu imatuluka ikatsekedwa.

Kuponderezana kwambiri: Torque yokwera kwambiri, kukalamba msanga kwa mphira.

2.2 Kodi mawonekedwe a chimbale chowongoleredwa bwino ndi mphamvu zambiri?

Maonedwe wamba: Ma disc owongolera a valve amatha kuchepetsa kutsika kwapanikizidwe.

Izi ndi zoona molingana ndi chiphunzitso cha "fluid mechanics", koma sizikugwira ntchito kwenikweni pakugwiritsa ntchito ma Vavu a Gulugufe Okhazikika.

Chifukwa:

Gwero lalikulu la kutayika kwa mphamvu mu ma valve a butterfly si mawonekedwe a valavu, koma "micro-channel effect" chifukwa cha kutsika kwa mphira wa valavu. Disiki ya valve kukhala yowonda kwambiri ikhoza kulephera kupereka mphamvu yokwanira yolumikizana, zomwe zingayambitse mizere yosindikizira yosalekeza ndi kutayikira.

Chidutswa chowongolera cha valve chingayambitse kupsinjika kwambiri pa rabara, kuchepetsa moyo wake.

Chifukwa chake, mapangidwe a mavavu agulugufe okhala mofewa amaika patsogolo "kukhazikika kwa mzere wosindikizira" kuposa kuwongolera.

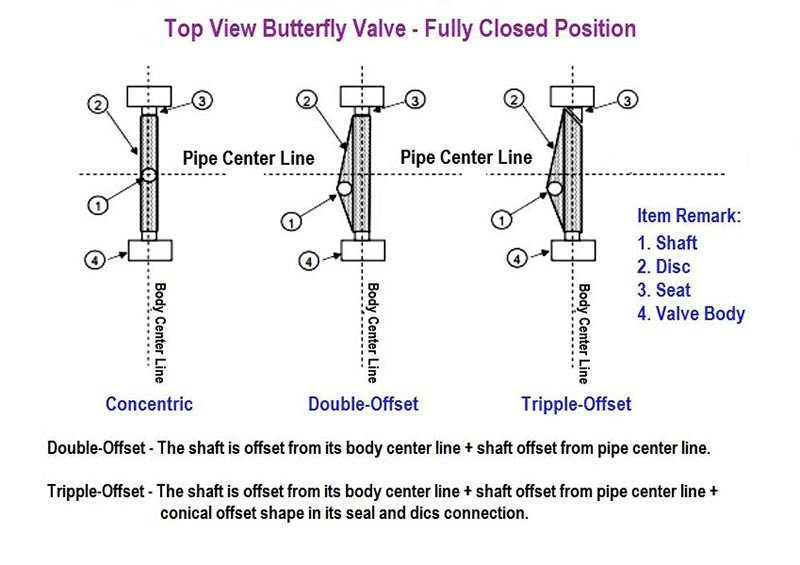

2.3 Mavavu agulugufe okhala mofewa amakhala ndi mzere wapakati

Nthawi zambiri zimanenedwa pa intaneti kuti ma eccentric agulugufe mavavu ayenera kugwiritsa ntchito zisindikizo zolimba zazitsulo.

Komabe, zochitika zenizeni zapadziko lapansi zikuwonetsa kuti:

Kulumikizana kawiri kumapangitsa kuti moyo wa Resilient Butterfly Valves ukhale wabwino.

Chifukwa:

Kuphatikizika kawiri: Valve disc imangolumikizana ndi mphira panthawi yomaliza ya 2-3 ° yotseka, kuchepetsa kwambiri kukangana.

Ma torque otsika, zomwe zimapangitsa kuti pakhale kusankha kogwiritsa ntchito ndalama zambiri.

2.4 Chofunikira chachikulu pampando wa rabara ndi "dzina lazinthu"*

Ogwiritsa ntchito ambiri amangoganizira za:

Chithunzi cha EPDM

NBR

Viton (FKM)

Koma zomwe zimakhudza kwambiri moyo ndi izi:

2.4.1 Kulimba kwa magombe:

Mwachitsanzo, kuuma kwa Shore A kwa EPDM si nkhani ya "yofewa bwino." Nthawi zambiri, 65-75 ndiye mulingo woyenera kwambiri, kukwaniritsa zero kutayikira pa kupanikizika kochepa (PN10-16).

Yofewa kwambiri: Torque yochepa koma yong’ambika mosavuta. M'malo othamanga kwambiri (> 2 MPa) kapena malo achipwirikiti, mphira wofewa umaponderezedwa kwambiri, zomwe zimapangitsa kuti ma extrusion asinthe. Kuphatikiza apo, kutentha kwambiri (>80 ° C) kumachepetsanso mphira.

Zovuta kwambiri: Zovuta kusindikiza, makamaka m'makina otsika kwambiri (<1 MPa), kumene mphira sungathe kupanikizidwa mokwanira kuti apange mawonekedwe a mpweya, zomwe zimatsogolera ku micro-leakage.

2.4.2 Vulcanization kutentha ndi kuchiritsa nthawi

Kutentha kwa Vulcanization ndi kuchiritsa nthawi kumayang'anira kulumikizana kwa mphira unyolo wa molekyulu, zomwe zimakhudza mwachindunji kukhazikika kwa mawonekedwe a netiweki ndikuchita kwanthawi yayitali. Mtundu wofananira ndi 140-160 ° C, 30-60 mphindi. Kutentha kwambiri kapena kutsika kwambiri kumabweretsa kuchiritsa kosagwirizana ndi kukalamba msanga. Kampani yathu nthawi zambiri imagwiritsa ntchito vulcanization yamagawo angapo (kuchiritsa kusanachitike 140 ° C, kutsatiridwa ndi kuchiritsa pambuyo pa 150 ° C). 2.4.3 Compression Set

Kuponderezedwa kumatanthawuza kuchuluka kwa kusinthika kosatha komwe mphira amakumana ndi kupsinjika kosalekeza (nthawi zambiri 25% -50% kuponderezedwa, kuyesedwa pa 70 ° C / 22h, ASTM D395) ndipo sangathe kuchira. Mtengo woyenera wa compression set ndi <20%. Mtengo uwu ndi "bottleneck" kusindikiza kwa nthawi yayitali kwa valve; Kuthamanga kwanthawi yayitali kumabweretsa mipata yokhazikika, kupanga mfundo zotayikira.

2.4.4 Kulimba Kwambiri

A. Mphamvu Yamphamvu (kawirikawiri> 10 MPa, ASTM D412) ndizovuta kwambiri zomwe mphira ungathe kupirira musanayambe kusweka, ndipo ndizofunikira kwambiri kuti zisawonongeke komanso kutsekedwa kwa mpando wa valve. Zomwe zili mu rabara ndi chiŵerengero cha kaboni wakuda zimatsimikizira mphamvu yolimba ya mpando wa valve.

Mu mavavu agulugufe, amakana kumeta ubweya ndi ma valve disc m'mphepete ndi kukhudza kwamadzimadzi.

2.4.5 Choopsa chachikulu chobisika cha mavavu agulugufe ndi kutayikira.

Pangozi zauinjiniya, kutayikira nthawi zambiri si vuto lalikulu, koma kuwonjezeka kwa torque.

Zomwe zimayambitsa kulephera kwadongosolo ndi:

Kuthamanga kwadzidzidzi kwa torque → kuwonongeka kwa zida za nyongolotsi → kugunda kwamagetsi → kutsekeka kwa ma valve

Chifukwa chiyani torque ikuwonjezeka mwadzidzidzi?

- Kukulitsa kutentha kwa mpando wa valve

- Mayamwidwe amadzi ndikukula kwa mphira (makamaka EPDM yotsika kwambiri)

- Kusintha kosatha kwa mphira chifukwa cha kupsinjika kwa nthawi yayitali

- Kupanga kolakwika kwa kusiyana pakati pa tsinde la valve ndi diski ya valve

- Mpando wa vavu sunathyoledwe bwino mutasinthidwa

Choncho, "torque curve" ndi chizindikiro chofunika kwambiri.

2.4.6 Kulondola kwa makina a valve sikofunikira.

Anthu ambiri amakhulupirira molakwika kuti kusindikizidwa kwa ma valve agulugufe okhala mofewa makamaka kumadalira mphira, kotero kuti makina olondola a ma valve a thupi sali apamwamba.

Izi ndi zolakwika kwathunthu.

Kulondola kwa thupi la valve kumakhudza:

Kuzama kwa mavavu pampando → kupanikizana kosindikiza kosindikiza, komwe kumapangitsa kusaloleza bwino pakutsegula ndi kutseka.

Kusagwedezeka kosakwanira kwa m'mphepete mwa poyambira → kukanda pakuyika mpando wa valve

Cholakwika pakati pa mtunda wa valve disc → kukhudzana kwambiri komwe kumachitika

2.4.7 Pakatikati pa "mavavu agulugufe okhala ndi rabala / PTFE" ndi chimbale cha valve.

Pakatikati pa mphira wathunthu kapena mawonekedwe a PTFE sikuyenera "kukhala ndi malo okulirapo omwe amawoneka osamva dzimbiri," koma kutsekereza sing'anga kuti isalowe mumayendedwe ang'onoang'ono mkati mwa valavu. Mavuto ambiri okhala ndi mavavu agulugufe otsika mtengo sali chifukwa cha mphira wopanda pake, koma m'malo mwake:

"Mpata wooneka ngati mphero" pa mphambano ya mpando wa valve ndi thupi silinakonzedwe bwino.

Kukokoloka kwa madzi kwa nthawi yayitali → ma microcracks → kuphulika kwa mphira ndi kuphulika

Gawo lomaliza ndikulephera kwapadera kwa mpando wa valve.

3. N'chifukwa chiyani ma Vavu a Gulugufe Okhazikika amagwiritsidwa ntchito padziko lonse?

Kupatula mtengo wotsika, zifukwa zitatu zozama ndi izi:

3.1. Kulekerera kwamphamvu kwambiri

Poyerekeza ndi zisindikizo zachitsulo, zisindikizo za mphira, chifukwa cha kusungunuka kwawo kwambiri, zimakhala ndi kulolerana kwakukulu kwa kupatuka kwa unsembe ndi kupunduka pang'ono.

Ngakhale zolakwika zopangira zitoliro, kupatuka kwa flange, komanso kupsinjika kwa bawuti kosagwirizana kumatengera kulimba kwa mphira (zowona, izi ndizochepa komanso zosafunika, ndipo zidzawononga payipi ndi valavu pakapita nthawi).

3.2. Kusinthika kwabwino kwambiri pakusinthasintha kwamakasitomala

Zisindikizo za mphira sizikhala ngati "zowonongeka" ngati zisindikizo zachitsulo; amalipiritsa okha chingwe chosindikizira panthawi ya kusinthasintha kwamphamvu.

3.3. Mtengo wotsikitsitsa wa moyo wonse

Mavavu agulugufe osindikizidwa mwamphamvu amakhala olimba, koma mtengo wake ndi wokwera mtengo.

Poyerekeza, ndalama zonse zogulira ndi kukonza ma Vavu a Resilient Butterfly ndizovuta kwambiri.

4. Mapeto

Mtengo waMavavu Agulugufe Okhazikikasikuti "kusindikiza kofewa"

Mavavu agulugufe osindikizidwa ofewa amatha kuwoneka osavuta, koma zinthu zabwino kwambiri zimathandizidwa ndi malingaliro okhwima aukadaulo, kuphatikiza:

Mapangidwe olondola a zone

Kuchita koyendetsedwa kwa rabara

Kufananiza kwa geometric kwa ma valve ndi tsinde

Njira yosonkhanitsa mipando ya valve

Kuwongolera torque

Kuyesa kuzungulira kwa moyo

Izi ndizomwe zimatsimikizira mtundu, osati "dzina lachinthu" ndi "mawonekedwe".

ZINDIKIRANI:* DATA imanena za tsamba ili:https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Nthawi yotumiza: Dec-09-2025