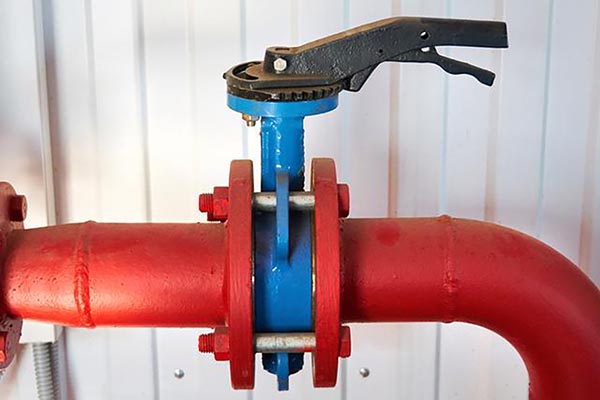

Mavavu agulugufe amagwiritsidwa ntchito poyambitsa, kuyimitsa kapena kuwongolera kutuluka kwa zakumwa kapena mpweya kudzera m'mapaipi. Amatenga dzina lawo kuchokera ku diski yonga mapiko yomwe imazungulira mkati mwa thupi la valve, yofanana ndi kayendedwe ka gulugufe. Pakati pa mitundu yosiyanasiyana ya mavavu agulugufe, ma valve agulugufe apamwamba (HPBV) ndi ma valve agulugufe omwe ali pafupi kwambiri ndi mapangidwe awiri omwe amapezeka kwambiri. Kuyerekeza uku kudzathetsa kusiyana pakati pa awiriwa kuchokera kumagulu angapo kuti afotokoze ntchito zawo m'mafakitale ndi ma municipalities.

| Mbali | Vavu ya Gulugufe Wapakati | Valovu ya Gulugufe Wapamwamba |

| Kupanga | Central tsinde ndi disc | Tsinde la offset ndi mpando wachitsulo |

| Njira Yosindikizira | Mpando wofewa wa elastomeric | Mpando wa RPTFE |

| Pressure Rating | Mpaka 250 PSI | Mpaka 600 PSI |

| Kutentha Mayeso | Kufikira 180°C (356°F) | Kufikira 260°C (536°F) |

| Valani & Kugwetsa | Zapamwamba chifukwa chokhudzana ndi mpando | Kutsika chifukwa cha kapangidwe ka offset |

| Kugwiritsa Ntchito Kuyenerera | Madzi otsika kwambiri | Kuthamanga kwapakati, madzi otentha kwambiri |

| Mtengo | Pansi | Zapamwamba |

1. Kupanga ndi Kumanga

Kusiyana kwakukulu pakati pa mavavu agulugufe okhazikika ndi ma valve agulugufe ochita bwino kwambiri kumakhala pamapangidwe ake, makamaka malo a tsinde la valavu ndi diski ya valve mogwirizana ndi thupi la valavu ndi zida zomwe zimagwiritsidwa ntchito.

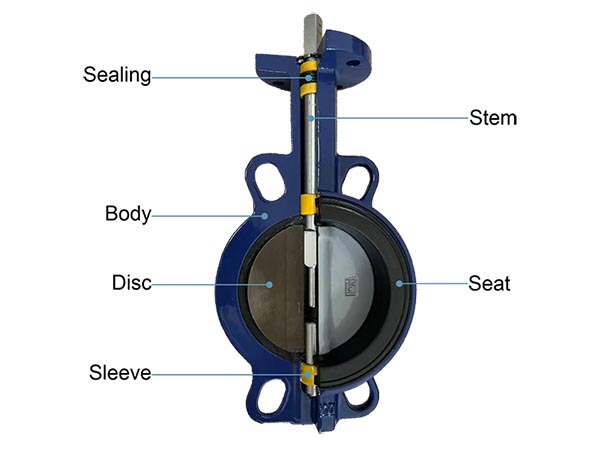

1.1 Ma Vavu Agulugufe Okhazikika

Mapangidwe apakati amadziwika kuti "zero offset" kapena "silient seat" valve, kulumikiza tsinde la valavu ndi diski ya valve mwachindunji pakati pa thupi la valve ndi chitoliro. Kuyang'ana pakati uku kulibe chopotoka.

1.1.1 Kusuntha kwa Diski

Diskiyo imazungulira 90 ° mozungulira tsinde la valve, ndipo imayenda kuchokera kutseguka kwathunthu (mofanana ndi chitoliro) mpaka kutsekedwa kwathunthu (perpendicular to pipe) mumayendedwe ake onse.

1.1.2 Njira Yosindikizira

Chisindikizocho chimatheka chifukwa cha kusokoneza pakati pa m'mphepete mwa diski ya valve ndi mpando wokhazikika wa mphira wofanana ndi mphira (monga EPDM, acrylic kapena fluororubber) yomwe imakhala mkati mwa thupi la valve.

1.1.3 Zipangizo

Thupi la valve nthawi zambiri limapangidwa ndi zinthu zamphamvu kwambiri komanso zolimbana ndi dzimbiri monga chitsulo choponyedwa, chitsulo cha ductile kapena chitsulo chosapanga dzimbiri kuti zigwiritsidwe ntchito movutikira, chifukwa mpando wa valve wa rabara umalepheretsa kukhudzana kwamadzi ndi valavu.

Chimbalecho chikhoza kukhala chitsulo chosapanga dzimbiri, mkuwa wa aluminiyamu, chitsulo chachitsulo chosapanga dzimbiri, kapena chokhala ndi chitsulo chokwanira, malingana ndi kuwonongeka kwa madzi.

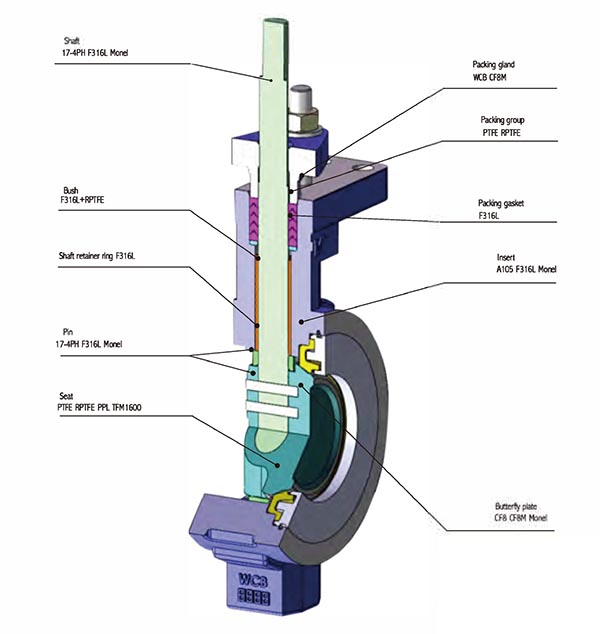

1.2 Ma Vavu Agulugufe Ogwira Ntchito Kwambiri

Kawirikawiri mapangidwe awiri-offset okhala ndi mafungulo awiri:

Tsinde lili kuseri kwa chimbale osati kudutsa pakati pa chimbale, ndi

Kusonkhana kwa diski ndi tsinde kumachotsedwa pakatikati pa chitoliro choboola.

Matembenuzidwe ena apamwamba amaphatikizapo kuchotseratu katatu, koma kubwereza kawiri kumakhala kofanana ndi machitidwe apamwamba.

1.2.1 Kusuntha kwa Diski

Chifukwa cha kusinthika, chimbale chimazungulira ngati cam-chinthu, kuchepetsa kukhudzana ndi mpando.

1.2.2 Njira Yosindikizira

Mpandowo umapangidwa ndi zinthu zolimba kwambiri, monga Teflon yolimbikitsidwa, kuti athe kupirira zovuta komanso kutentha kwambiri. Mosiyana ndi mpando wa rabara mu valavu yokhazikika, chisindikizocho ndi cholimba komanso sichidalira mapindikidwe.

1.2.3 Zipangizo

Thupi ndi ma disc amapangidwa ndi zitsulo zolimba, monga chitsulo chosapanga dzimbiri, chitsulo cha kaboni, kapena ma alloys, kuti athe kupirira zovuta.

1.3 Mwachidule: Zotsatira Zapangidwe

Kuphweka kwa valve concentric kumapangitsa kuti ikhale yopepuka komanso yophatikizika, ndikupangitsa kuti ikhale yoyenera kukhazikitsa mwachindunji. Komabe, kudalira kwake pampando wa rabara wopunduka kumalepheretsa kusinthasintha kwake.

Kukonzekera kwazitsulo ndi zipangizo zamphamvu za ma valve ochita bwino kwambiri kumapangitsa kuti zikhale zolimba komanso zosinthika, koma chifukwa cha kuchuluka kwa zovuta komanso kulemera kwake.

---

2. Mphamvu Zochita

Magwiridwe ndi gawo losinthika kwambiri la ma valve awa komanso omwe ogwiritsa ntchito amawakonda ndikusamala kwambiri. Mwachindunji, amawunikidwa malinga ndi kupanikizika, kutentha, kusindikiza ndi moyo wautumiki.

2.1 Ma Vavu Agulugufe Okhazikika

2.1.1 Makonda a Pressure

Mavavu agulugufe okhazikika amatha kupirira kukakamiza mpaka PN16, koma izi zimasiyanasiyana kutengera kukula ndi zinthu. Pamwamba pa kukakamiza uku, mpando wa rabara ukhoza kufooketsa kapena kulephera.

2.1.2 Mavoti a Kutentha

Kutentha kwakukulu ndi 356 ° F (180 ° C), kochepa ndi malire a kutentha kwa mpando wa rabara kapena PTFE. Kutentha kwakukulu kumasokoneza ntchito ya elastomer ndikusokoneza kusindikiza.

2.1.3 Kusindikiza ntchito

Ikhoza kupereka kutsekedwa kodalirika mu machitidwe otsika, koma kukangana kosalekeza pakati pa diski ya valve ndi mpando wa valve kumayambitsa kuvala, zomwe zidzachepetsa mphamvu.

2.1.4 Kuthamanga

Popeza ma valve a butterfly ndi oyenera kutsegulira ndi kutseka kwathunthu, ngati agwiritsidwa ntchito poyendetsa kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake kake.

2.1.5 Kukhalitsa

Kukhala zotanuka kwambiri, zitsulo kapena zitsulo mipando valavu ndi cholimba kuposa mphira. Mapangidwe a offset amakulitsanso moyo wautumiki pochepetsa mikangano.

2.2 Vavu yagulugufe yogwira ntchito kwambiri

2.2.1 Mlingo wazovuta

Chifukwa cha kapangidwe kake kolimba komanso kapangidwe kake komwe kamachepetsa kupsinjika pampando wa valve, imatha kupirira zovuta mpaka PN16.

2.2.2 Kutentha kwa kutentha

Popeza mpando wa valve umagwiritsa ntchito RPTFE, ukhoza kugwira ntchito bwino pa kutentha mpaka 536 ° F (280 ° C).

2.2.3 Kusindikiza ntchito

Chifukwa cha kukwanira bwino kwa disc valve offset ndi mpando wokhazikika wa valve, kutayikira kumakhala pafupifupi ziro ndipo nthawi zambiri kumakhala pafupi ndi kutseka kwa mpweya. Izi zimapangitsa kuti ikhale yabwino kwa mapulogalamu ovuta.

2.2.4 Kuthamanga

Zomangamanga ndi zipangizo zomwe zimagwiritsidwa ntchito mu ma valve agulugufe ogwira ntchito kwambiri zimawathandiza kuti aziyendetsa bwino kuyenda ngakhale pazovuta kwambiri. Kuchepetsa kukhudzana kwa mipando kumachepetsa kutha komanso kumapangitsa kuti chisindikizo chikhale chokhazikika pakanthawi kangapo.

2.2.5 Kukhalitsa

Kukhala olimba kwambiri, mipando yachitsulo kapena yokhazikika imakhala yolimba kuposa mphira. Mapangidwe a offset amakulitsanso moyo wautumiki pochepetsa mikangano.

2.3 Chidule Chachidule: Zowonetsa Kachitidwe

Ma valve okhazikika ndi oyenerera kutsika kwapansi, mikhalidwe yokhazikika, koma amalephera pamikhalidwe yapakatikati ndi yapamwamba.

Ma valve ochita bwino kwambiri amapereka kudalirika kwapamwamba komanso moyo wautumiki pamtengo wapamwamba woyambira.

---

3. Mapulogalamu

Kusankha pakati pa mavavu agulugufe apakati ndi ma valve agulugufe ochita bwino kwambiri zimadalira zosowa zenizeni za dongosolo lomwe amayikidwa.

3.1 Ma Vavu Agulugufe Okhazikika

Kwa machitidwe otsika kapena apakati / kutentha komwe mtengo ndi kuphweka ndizofunikira.

Kagwiritsidwe Ntchito Kamodzi:

- Madzi ndi Madzi Otayira: Madzi am'matauni, zothirira ndi zimbudzi zimapindula ndi chuma chawo komanso kudzipatula kwamadzimadzi.

- Chakudya ndi Mankhwala: Mipando ya mphira imalepheretsa madzi amadzimadzi kuti asaipitsidwe ndi ma valve.

- Kupereka kwa Gasi: Mizere yamafuta otsika amawagwiritsa ntchito poyatsa/kuzimitsa.

- Chitetezo Pamoto: Makina opaka utoto amatengera mwayi wogwiritsa ntchito mwachangu komanso kudalirika pazovuta zapakatikati.

- Mpweya Wotsika: Wotentha mpaka 250 PSI ndi 350°F.

3.2 Ma Vavu Agulugufe Ogwira Ntchito Kwambiri

Pazovuta zapakatikati kapena machitidwe ovuta omwe amafunikira kulondola komanso kukhazikika.

Kagwiritsidwe Ntchito Kamodzi:

- Mafuta ndi Gasi: Imasamalira mankhwala owopsa, mafuta a petrochemicals, komanso madera akunyanja omwe ali ndi mphamvu zambiri komanso madzi akuwononga.

- Kupanga Mphamvu: Imawongolera nthunzi yothamanga kwambiri komanso madzi ozizira m'ma turbines ndi ma boilers.

- Chemical Processing: Imakana zamadzimadzi zowononga ndipo imasunga kutsekeka kolimba m'malo osakhazikika.

- HVAC: Pamakina akulu omwe amafunikira kuwongolera kolondola.

- Kupanga zombo: Kumalimbana ndi mikhalidwe yam'madzi komanso kuyendetsa bwino kwamadzimadzi.

3.3 Kuphatikizika kwa Ntchito ndi Kusiyanasiyana

Ngakhale kuti ma valve onsewa amayang'anira kayendedwe kake, ma valve okhazikika amalamulira m'madera otsika mtengo, osowa kwambiri, pamene ma valve ochita bwino kwambiri amawakonda pazochitika za mafakitale kumene kulephera kungakhale ndi zotsatira zoopsa.

---

4. Kuganizira za Ntchito

Kuphatikiza pakupanga ndi kugwiritsa ntchito, zinthu zothandiza monga kukhazikitsa, kukonza, ndi kuphatikiza koyenera kwadongosolo zimagwiranso ntchito.

4.1 Kuyika

- Concentric: Kuyika kosavuta chifukwa cha kulemera kwake komanso kugwirizana kosavuta kwa flange.

- Kuchita bwino: Kuyanjanitsa kolondola kumafunika chifukwa cha kapangidwe kake, ndipo kulemera kwake kumafunikira chithandizo champhamvu.

4.2 Kusamalira

- Kukhazikika: Kukonza kumayang'ana pakusintha mpando wa rabara, womwe ndi njira yokonzekera mwachangu komanso yotsika mtengo. Komabe, kuvala pafupipafupi kumatha kukulitsa nthawi yocheperako pamakina apamwamba kwambiri.

- Kuchita bwino kwambiri: Kukonza sikuchitika kawirikawiri chifukwa chokhala ndi mpando wokhazikika, koma kukonza (mwachitsanzo, kuchotsa mpando) kumakhala kokwera mtengo komanso kwaukadaulo, nthawi zambiri kumafunikira akatswiri okonza zida ndi zida zapadera.

4.3 Pressure Drop

- Concentric: Ma disks omwe ali pakati amapanga chipwirikiti akamatseguka pang'ono, amachepetsa magwiridwe antchito.

- Kuchita Kwapamwamba: Ma disks a Offset amawongolera mawonekedwe otaya, amachepetsa cavitation ndi kutsika kwamphamvu, makamaka pa liwiro lalikulu.

4.4 Zochita

Mavavu onsewa atha kugwiritsidwa ntchito ndi makina opangira ma manual, pneumatic, kapena magetsi, koma ma valve ochita bwino kwambiri nthawi zambiri amaphatikizidwa ndi zowongolera zapamwamba kuti zizitha kukhazikika m'mafakitale.

---

5. Kusanthula Mtengo ndi Moyo Wozungulira

5.1 Mtengo Woyamba

Ma valve okhazikika ndi otsika mtengo kwambiri chifukwa ndi osavuta kupanga komanso kugwiritsa ntchito zinthu zochepa. Izi sizili choncho ndi ma valve agulugufe ogwira ntchito kwambiri.

5.2 Mtengo Wozungulira Moyo

Ma valve ogwira ntchito kwambiri nthawi zambiri amakhala otsika mtengo pakapita nthawi chifukwa sasamalidwa pafupipafupi ndikusinthidwa. Mu machitidwe ovuta, kudalirika kwawo kungathenso kuchepetsa mtengo wa nthawi yopuma.

---

6. Kutsiliza: Chidule cha Ubwino ndi Kuipa kwake

6.1 Vavu ya Gulugufe Wapakati

6.1.1 Ubwino:

- Kutsika mtengo: Kutsika mtengo kwa kupanga ndi zinthu zakuthupi kumapereka mwayi pa bajeti.

- Mapangidwe osavuta: Osavuta kukhazikitsa, kugwiritsa ntchito, ndi kukonza, okhala ndi magawo ochepa osuntha.

- Kudzipatula kwamadzimadzi: Mipando ya mphira imateteza thupi la valve, kulola kugwiritsa ntchito zinthu zotsika mtengo komanso kusunga chiyero chamadzimadzi.

- Wopepuka: Ndiwoyenera kugwiritsa ntchito pomwe kulemera kumadetsa nkhawa.

6.1.2 Zoyipa:

- Zochepa zochepa: Malire apamwamba ndi 250 PSI ndi 356 ° F, kuchepetsa kugwiritsidwa ntchito kwake kuzinthu zovuta.

- Itha kuvala: Kusemphana kwa mipando nthawi zonse kumatha kupangitsa kuti ntchito ikhale yonyozeka, zomwe zimafunikira kukonzanso pafupipafupi.

- Kusagwira bwino ntchito kwamphamvu kwambiri: Kumataya kulondola komanso kusindikiza pansi pamavuto.

6.2 Ma Vavu Agulugufe Ogwira Ntchito Kwambiri

6.2.1 Ubwino:

- Kuthekera Kwapamwamba: Imatha kuthana ndi zovuta zapakatikati mpaka zazikulu (mpaka 600 PSI) ndi kutentha (mpaka 536 ° F).

- Moyo Wautumiki Wautali: Kuchepetsa kuvala kwa mipando ndi zida zolimba zimakulitsa moyo wautumiki.

- Kulondola: Kuthamanga kwabwino komanso kutsekeka ngakhale pakufunika.

- Kusinthasintha: Ndikoyenera kumadzimadzi ndi malo osiyanasiyana.

6.2.2 Zoyipa:

- Mtengo Wokwera: Zida zodula komanso mapangidwe ovuta amawonjezera ndalama zam'tsogolo.

- Kuvuta: Kuyika ndi kukonza kumafuna ukadaulo wochulukirapo.

- Kulemera kwake: Kumanga kolemera kumatha kusokoneza kukonzanso makina ena.

Ma valve agulugufe okhazikika komanso ma valve agulugufe ochita bwino kwambiri amagwira ntchito modutsana koma madera osiyanasiyana pakuwongolera madzimadzi. Mapangidwe a mipando ya rabara ya zero-offset ya valve concentric imapangitsa kuti ikhale yothandiza komanso yotsika mtengo yopangira ntchito zochepetsetsa monga madzi, kukonza chakudya kapena kuteteza moto. Ngati kugwira ntchito ndi kulimba mtima sikungakambirane, ndiye kuti valavu ya butterfly yapamwamba ndiyo yankho. Pazinthu zokwiriridwa (monga mapaipi apansi panthaka), njira zonse ziwirizi zitha kugwiritsidwa ntchito, koma kulemera kocheperako komanso kutsika mtengo kwa vavu yopindika nthawi zambiri kumakhalapo pokhapokha ngati zinthu zitavuta.