Mu gawo la mafakitale owongolera madzimadzi,valavu butterflyzimagwira ntchito yofunika kwambiri pakuwongolera, kuwongolera, ndikupatula mayendedwe amadzimadzi, mpweya, ndi matope m'mapaipi. Valavu yagulugufe ya flanged ndi mtundu umodzi wolumikizirana, womwe umakhala ndi ma flanges mbali zonse ziwiri za thupi la valve, zomwe zimalola kulumikizana kotetezedwa ndi zitoliro.

Njira yozungulira kotala ya avalavu ya butterflyamachisiyanitsa ndi mavavu amzere monga zipata kapena ma globe mavavu, opereka maubwino pakuthamanga komanso kuchita bwino kwa danga.

Nkhaniyi idzafufuza mwatsatanetsatane ma valve a butterfly, kuphimba mapangidwe awo, mitundu, zipangizo, ntchito, ubwino ndi kuipa, kukhazikitsa, kukonza, kufananitsa ndi ma valve ena, ndi zochitika zamtsogolo.

1. Tanthauzo ndi Mfundo Yoyendetsera Ntchito

Valavu yagulugufe ya flanged ndi valavu yoyendayenda ya 90-degree yomwe imadziwika ndi diski yomwe imayang'anira kutuluka kwa madzi kudzera mu kuzungulira kwa tsinde. Thupi la valavu limakhala ndi ma flange mbali zonse ziwiri kuti zilumikizidwe molunjika ku mapaipi. Ma valve a butterfly a Flange amakhala ndi ma flanges okwera kapena ophwanyika okhala ndi mabowo a bawuti, omwe amapereka kulumikizana kwamphamvu komanso kokhazikika koyenera kugwiritsa ntchito zotsika, zapakatikati, komanso zopanikizika kwambiri, komanso ma diameter ang'onoang'ono, apakati, ndi akulu.

Mfundo yoyendetsera ntchito ndi yosavuta komanso yothandiza. Vavu imakhala ndi thupi la valve, valavu disc, tsinde la valve, mpando wa valve, ndi actuator. Pamene chogwiritsira ntchito kapena zida zikugwiritsidwa ntchito, kapena tsinde la valve likuyendetsedwa ndi makina opangira makina, diski ya valve imazungulira kuchokera kumalo omwe ali ofanana ndi njira yothamanga (yotseguka mokwanira) kupita kumalo ozungulira (kutsekedwa kwathunthu). Pamalo otseguka, diski ya valve imalumikizidwa ndi mayendedwe a mapaipi, kuchepetsa kukana kwakuyenda komanso kutayika kwamphamvu. Akatsekedwa, valavu ya valve imasindikiza pampando mkati mwa thupi la valve.

Makinawa amalola kuti ma valve azitha kugwira ntchito mwachangu, zomwe zimangofuna kusinthasintha kwa digirii 90, ndikupangitsa kuti ikhale yachangu kuposa ma valve otembenuza ambiri. Mavavu agulugufe ang'onoang'ono amatha kuyenda mozungulira mbali ziwiri ndipo amakhala ndi mipando yolimba kapena yachitsulo kuti atseke. Mapangidwe awo amawapangitsa kukhala oyenera makamaka pamakina omwe amafunikira kusintha pafupipafupi kapena pomwe malo ali ochepa.

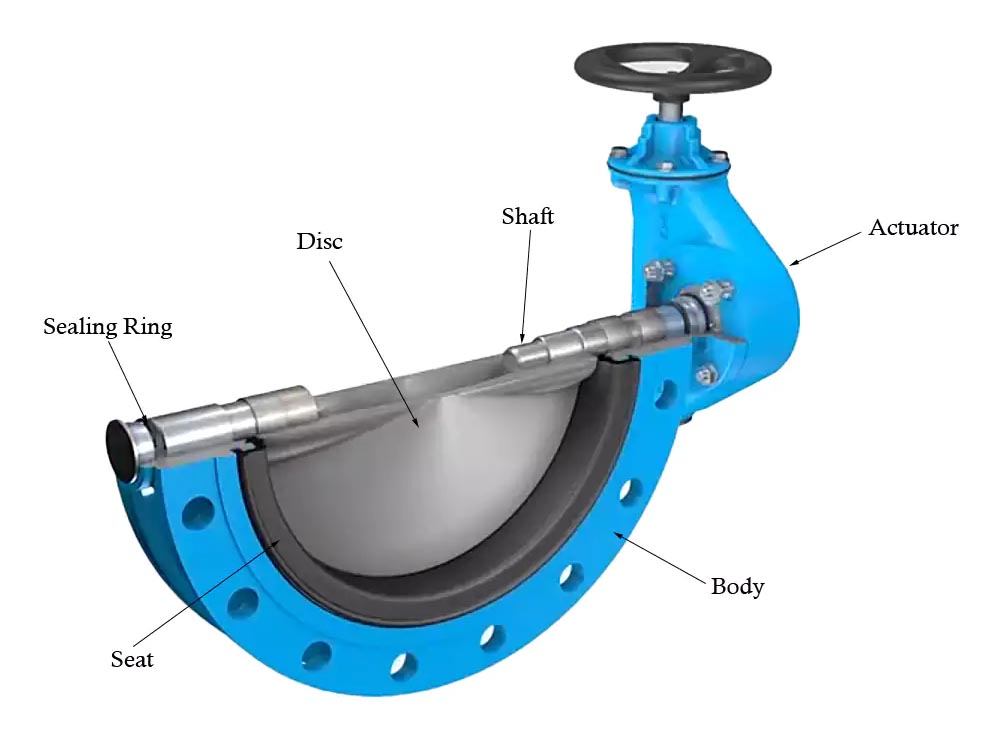

2. Zigawo

Zigawo zikuluzikulu zikuphatikiza:

- Thupi la Vavu: Nyumba yakunja, yomwe nthawi zambiri imakhala yomanga pawiri, imapereka malumikizano apangidwe ndikukhala ndi zigawo zamkati. Chitsulo cha kaboni chimagwiritsidwa ntchito wamba, chitsulo chosapanga dzimbiri polimbana ndi dzimbiri, mkuwa wa nickel-aluminiyamu m'malo am'madzi, ndi chitsulo cha alloy pazovuta kwambiri.

- Valve disc:Chinthu chozungulira, chomwe chimapezeka m'mapangidwe osavuta kapena osalala, chimayendetsa kayendedwe kake. Diski ikhoza kukhala pakati kapena kusinthidwa kuti ipititse patsogolo magwiridwe antchito. Chitsulo chosapanga dzimbiri, mkuwa wa aluminiyamu, kapena wokutidwa ndi nayiloni kuti musamavalidwe bwino.

- Tsinde: Shaft yolumikiza disc ya valve ku actuator imatumiza mphamvu yozungulira. Chitsulo chosapanga dzimbiri kapena zotayira zamphamvu kwambiri zimapirira torque.

Kupyolera mu shaft kapena zigawo ziwiri zimagwiritsidwa ntchito nthawi zambiri, zokhala ndi zisindikizo kuti zisatayike.

- Mpando: Malo osindikizira amapangidwa ndi zinthu za elastomeric monga EPDM kapena PTFE. EPDM (-20°F mpaka 250°F), BUNA-N (0°F mpaka 200°F), Viton (-10°F mpaka 400°F), kapena PTFE (-100°F ku 450°F) amagwiritsidwa ntchito pazisindikizo zofewa; zitsulo monga zitsulo zosapanga dzimbiri kapena Inconel zimagwiritsidwa ntchito pazisindikizo zolimba zotentha kwambiri.

- Woyambitsa: Imagwira ntchito pamanja (chogwira, giya) kapena yoyendetsedwa (mapneumatic, magetsi).

- Kupaka ndi gaskets: Onetsetsani kuti zisindikizo zothina zotayikira pakati pa zigawo ndi zolumikizira za flange.

Zigawozi zimagwira ntchito limodzi kuti zipereke ulamuliro wodalirika woyenda.

3. Mitundu ya Flanged Butterfly Valves

Ma valve agulugufe a Flanged akhoza kugawidwa motere kutengera ma disc, njira yoyendetsera, ndi mtundu wa thupi.

3.1 Kulumikizana

- Concentric (zero offset): Tsinde la valve limadutsa pakati pa diski ndikukhala ndi mpando wokhazikika. Valavu iyi ndi yoyenera kugwiritsa ntchito zocheperako komanso kutentha mpaka 250°F.

- Kuyimitsa kawiri: Tsinde la valve limachotsedwa kuseri kwa diski ndikuchotsa pakati, kuchepetsa kuvala kwa mipando. Vavu iyi ndi yoyenera kugwiritsa ntchito pakatikati-pakatikati komanso kutentha mpaka 400°F.

- Kuchepetsa katatu: Kukwera kwapampando wokwera kumapanga chisindikizo chachitsulo mpaka chitsulo. Vavu iyi ndi yoyenera kuthamanga kwambiri (mpaka Class 600) komanso kutentha kwambiri (mpaka 1200).°F) kugwiritsa ntchito ndikukwaniritsa zofunikira za zero-leakage.

3.2 Njira yochitira

Mitundu ya actuation imaphatikizira pamanja, pneumatic, magetsi, ndi ma hydraulic kuti akwaniritse zofunikira zosiyanasiyana zogwirira ntchito.

4. Ntchito Zamakampani

Mavavu agulugufe a Flanged amagwiritsidwa ntchito kwambiri m'magawo otsatirawa:

- Chithandizo cha Madzi ndi Madzi Otayidwa: Amagwiritsidwa ntchito powongolera kayendedwe kazinthu zopangira mankhwala ndi njira zosinthira. - Kukonza Chemical: Kugwira ma acid, alkalis, ndi zosungunulira kumafuna zida zosagwira dzimbiri.

- Mafuta & Gasi: Kupaka mafuta osapsa, gasi wachilengedwe, ndi njira zoyenga.

- HVAC Systems: Imayang'anira kayendedwe ka mpweya ndi madzi pakutenthetsa ndi kuzirala.

- Kupanga Mphamvu: Imawongolera nthunzi, madzi ozizira, ndi mafuta.

- Chakudya & Chakumwa: Kapangidwe kaukhondo pakuwongolera madzi a aseptic.

- Mankhwala: Kuwongolera molondola m'malo osabala.

- Marine & Pulp & Paper: Amagwiritsidwa ntchito ngati madzi am'nyanja, zamkati, komanso kukonza mankhwala.

5. Ubwino ndi Kuipa kwa Flange Butterfly Valves

5.1 Ubwino:

- Yophatikizana komanso yopepuka, kuchepetsa mtengo woyika komanso zofunikira zamalo.

- Kugwira ntchito mwachangu kwa kotala ndikuyankha mwachangu.

- Kutsika mtengo kwa ma diameter akulu.

- Kutsika kwamphamvu kwapang'onopang'ono kukakhala kotseguka, kogwiritsa ntchito mphamvu komanso kothandiza.

- Yoyenera kusintha kwamadzimadzi ndikuchita bwino kwambiri kusindikiza.

- Yosavuta kuyisamalira komanso yogwirizana ndi makina opangira makina.

5.2 Zoyipa:

- Disiki ya valve imatseka njira yotuluka ikatseguka, zomwe zimapangitsa kuti pakhale kupsinjika kwina. - Kuchepa kwamphamvu kwapang'onopang'ono pamapulogalamu apamwamba kwambiri, zomwe zitha kuyambitsa cavitation.

- Mipando yofewa ya valve imavala mwachangu kwambiri pama media abrasive.

- Kutseka msanga kungayambitse nyundo yamadzi.

- Mapangidwe ena amafunikira ma torque apamwamba apamwamba, omwe amafunikira ma actuators amphamvu.

6. Momwe Mungayikitsire Vavu ya Gulugufe

Pakuyika, gwirizanitsani valavu ndi flange ya chitoliro, kuonetsetsa kuti mabowo a bawuti akugwirizana.

Ikani gasket kuti asindikize.

Kutetezedwa ndi mabawuti ndi mtedza, kumangitsa mofanana kuti mupewe kupotoza.

Ma valve awiri-flange amafuna kuyanjanitsa mbali zonse ziwiri panthawi imodzi; mavavu amtundu wa lug amatha kumangidwa mbali imodzi panthawi.

Yang'anani ufulu woyenda wa disc poyendetsa valavu musanayambe kukanikiza.

Mukayika molunjika, tsinde la valve liyenera kuyimitsidwa mopingasa kuti matope asachulukane.

Nthawi zonse tsatirani malangizo a wopanga ndi miyezo yoyesera monga API 598.

7. Miyezo ndi Malamulo

Mavavu agulugufe a FlangedAyenera kutsatira mfundo zachitetezo ndi kugwirizana:

- Kupanga: API 609, EN 593, ASME B16.34. - Kuyesa: API 598, EN 12266-1, ISO 5208.

- Flanges: ASME B16.5, DIN, JIS.

- Zitsimikizo: CE, SIL3, API 607pa(chitetezo chamoto).

8. Kuyerekeza ndi Mavavu Ena

Poyerekeza ndi mavavu a pachipata, ma valve agulugufe opindika amagwira ntchito mwachangu komanso amapereka mphamvu zopumira, koma amalephera kuyenda pang'ono.

Poyerekeza ndi ma valve a mpira, amakhala okwera mtengo kwambiri pama diameter akulu, koma amataya mphamvu kwambiri pakutsegula.

Ma valve a Globe amapereka kuwongolera bwinoko, koma ndiakuluakulu komanso okwera mtengo.

Ponseponse, mavavu agulugufe amapambana pakugwiritsa ntchito malo ochepera komanso osakwera mtengo.